Postharvest conservation of three minimally processed cassava cultivars under cold storage

Abstract

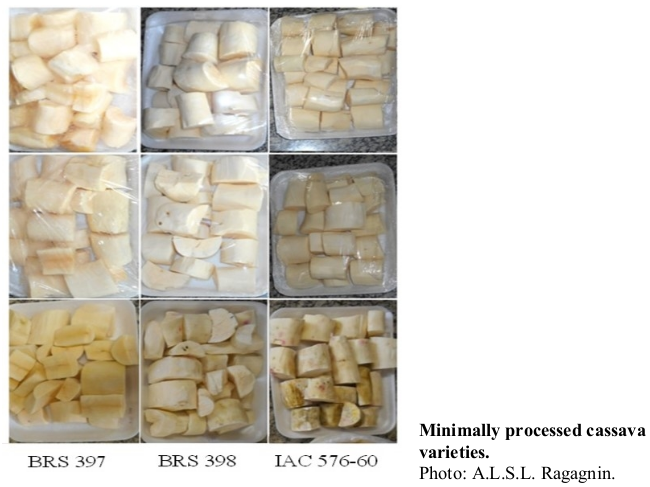

Once harvested and stripped of their bark, cassava roots have a short shelf life under ambient conditions. This is due to their high-water content, which makes them highly susceptible to attack by decaying fungi and the action of enzymes that darken the roots. After a few days of storage in ambient conditions, these roots become inedible. They show mold and vascular discoloration. For family farmers, keeping food frozen is a challenge due to the cost of freezing the food and especially due to the fact that the main means of selling their products is at street markets where there is no structure for installing freezers. This makes it necessary to know how the food behaves in a refrigerated environment. The objective of this study was to evaluate physical changes in cassava roots in LDPE packaging and PVC-wrapped polystyrene trays for three cultivars. Two experiments were conducted: experiment 1 involved low-density polyethylene (LDPE) packages with three cassava cultivars (BRS 397, BRS 398 e IAC 576-70), while experiment 2 used expanded polystyrene trays wrapped in polyvinyl chloride (PVC) with the same cultivars. The trials were carried out at Federal University of Jataí, Brazil. The experimental design was completely randomized design with three replications, with storage periods of 0, 5, 10, and 15 days. After pre-processing, the roots were packaged and stored in a refrigerated environment at 5±1°C. Measurements taken during storage included fresh weight loss, color difference, hue angle, and chroma. Overall, both packaging methods helped reduce mass loss of cassava roots stored at 5±1°C. The BRS 397 cultivar showed the lowest color difference over the course of the storage days, followed by the BRS 398 cultivar, which showed the same behavior as the BRS 397 cultivar until around 7 or 8 days, with an increase in color difference from then until the last day of storage.

Keywords

Manihot esculenta Crantz, Post-harvest deterioration, Low density polyethylene, Polyvinyl chloride, BRS 397, BRS 398, IAC 576-70

Author Biography

Alejandro Hurtado-Salazar

Departamento de Produccion Agropecuaria

References

- Alves, A., R.L. Cansian, G. Stuart, and E. Valduga. 2005. Alterações na qualidade de raízes de mandioca (Manihot esculenta Crantz) minimamente processadas. Ciênc. Agrotec. 29(2), 330-337. Doi: https://doi.org/10.1590/S1413-70542005000200009

- Andrade, D.P., F.A.L. Brito, M.J.B.C. Sá, M.R.S. Vieira, A.P. Barros Júnior, S.L.F. Silva, and A.N. Simões. 2014. Avaliação de cultivares de mandioca de mesa em diferentes idades de colheita. Interciência 39(10), 736-741.

- Ayetigbo, O., S. Latif, A. Abass, and J. Müller. 2021. Drying kinetics and effect of drying conditions on selected physicochemical properties of foam from yellow-fleshed and white-fleshed cassava (Manihot esculenta) varieties. Food Bioprod. Proces. 127, 454-464. Doi: https://doi.org/10.1016/j.fbp.2021.04.005

- Bonilla, R., J.L. Hoyos, and R. Velasco. 2013. Efecto de oxidación de almidón de yuca sobre propiedades mecánicas y térmicas de películas biodegradables. Biotecnol. Sector Agropecu. Agroind. 11(1), 208-217.

- Carbone, M., D.T. Donia, G. Sabbatella, and R. Antiochia. 2016. Silver nanoparticles in polymeric matrices for fresh food packaging. J. King Saud Univ. - Sci. 28(4), 273-279. Doi: https://doi.org/10.1016/j.jksus.2016.05.004

- Daramola, O., M. Idowu, O. Atanda, and C.R. Oguntona. 2010. Effects of packaging material on the quality of “pupuru” flour during storage. Afr. J. Food Sci. 4(5), 258-263.

- Grafiti LLC. 2020. SigmaPlot version 11.0, from Systat Software. In: www.systatsoftware.com; consulted: August, 2023.

- Henrique, C.M., P. Prati, and S.B.S. Sarmento. 2015. Alterações de cor em raízes de mandioca minimamente processadas e embaladas a vácuo. Rev. Iber. Tecnol. Postcosecha 16(1), 129-135.

- Hu, W., H. Kong, Y. Guo, Y. Zhang, Z. Ding, W. Tie, Y. Yan, Q. Huang, M. Peng, H. Shi, and A. Guo. 2016. Comparative physiological and transcriptomic analyses reveal the actions of melatonin in the delay of postharvest physiological deterioration of cassava. Front. Plant Sci. 7, 736. Doi: https://doi.org/10.3389/fpls.2016.00736

- IAC, Instituto Agronômico de Campinas Brazil. 2020. Mandioca IAC 576-70, cultivar de mesa. In: https://www.iac.sp.gov.br/cultivares/inicio/Folders/Mandioca/IAC576-70.htm; consulted: August, 2023.

- IBGE, Instituto Brasileiro de Geografia e Estatística. 2024. Censo Agropecuário: Agricultura Familiar. In: https://sidra.ibge.gov.br/tabela/6959#resultado; consulted: July, 2023.

- Iyer, S., D.S. Mattinson, and J.K. Fellman. 2010. Study of the early events leading to cassava root postharvest deterioration. Tropical Plant Biol. 3, 151-165. Doi: https://doi.org/10.1007/s12042-010-9052-3

- Jacob, A., I.P. Sudagar, R. Pandiselvam, P. Rajkumar, and M. Rajavel. 2023. Effect of packaging materials and storage temperature on the physicochemical and microbial properties of ultrasonicated mature coconut water during storage. Food Control, 149, 109693. Doi: https://doi.org/10.1016/j.foodcont.2023.109693

- Jorge, N. 2013. Embalagem para alimentos. Cultura Acadêmica; Universidade Estadual Paulista, São Paulo, Brazil.

- Konica Minolta. 2007. Precise color communication: color control from perception to instrumentation. In: https://www.konicaminolta.com/instruments/knowledge/color/pdf/color_communication.pdf; consulted: August, 2023.

- Nainggolan, E.A., J. Banout, and K. Urbanova. 2024. Recent trends in the pre-drying, drying, and post-drying processes for cassava tuber: a review. Foods 13(11), 1778. Doi: https://doi.org/10.3390/foods13111778

- Opara, U.L., and A. Mditshwa. 2013. A review on the role of packaging in securing food system: adding value to food products and reducing losses and waste. Afr. J. Agric. 8(22), 2621-2630. Doi: http://doi.org/10.5897/AJAR2013.6931

- Qin, Y., A.S.M. Djabou, F. An, K. Li, Z. Li, L. Yang, X. Wang, and S. Chen. 2017. Proteomic analysis of injured storage roots in cassava (Manihot esculenta Crantz) under postharvest physiological deterioration. Plos One 12(3), e0174238. Doi: https://doi.org/10.1371/journal.pone.0174238

- Osunde, Z.D. and A. Fadeyibi. 2012. Storage methods and some uses of cassava in Nigeria. Contin. J. Agric. Sci. 5(2), 12-18.

- Rinaldi, M.M., E.A. Vieira, and J.F. Fialho. 2015. Conservação pós-colheita de diferentes cultivares de mandioca submetidas ao processamento mínimo e congelamento. Científica 43(4), 287-301. Doi: https://doi.org/10.15361/1984-5529.2015v43n4p287-301

- Rinaldi, M.M., J.F. Fialho, E.A. Vieira, T.A.R. Oliveira, and S.F.O. Assis. 2017. Utilização de ácido cítrico para a conservação pós-colheita de raízes de mandioca. Braz. J. Food Technol. 20, e2017072. Doi: https://doi.org/10.1590/1981-6723.07217

- Salcedo, A., A. Del Valle, B. Sanchez, V. Ocasio, A. Ortiz, P. Marquez, and D. Siritunga. 2010. Comparative evaluation of physiological post-harvest root deterioration of 25 cassava (Manihot esculenta) accessions: visual vs. hydroxycoumarins fluorescent accumulation analysis. Afr. J. Agric. Res. 5(22), 3138-3144.

- SAS, Statistical Analysis System. 2013. SAS user ́s guide statistics v 9.4 (CR-ROM). SAS Institute, Cary, NC.

- Schudel, S., K. Shoji, C. Shrivastava, D. Onwude, and T. Defraeye. 2023. Solution roadmap to reduce food loss along your postharvest supply chain from farm to retail. Food Packag. Shelf Life 36, 101057. Doi: https://doi.org/10.1016/j.fpsl.2023.101057

- Tao, S., J. Wang, and J. Xie. 2024. Influence of different pre-cooling methods on the freshness preservation of bok choi (Brassica rapa var. chinensis). Food Chem. X 23, 101599. Doi: https://doi.org/10.1016/j.fochx.2024.101599

- Uarrota, V.G., R. Moresco, B. Coelho, E.C. Nunes, L.A.M. Peruch, E.O. Neubert, M. Rocha, and M. Maraschin. 2014. Metabolomics combined with chemometric tools (PCA, HCA, PLS-DA and SVM) for screening cassava (Manihot esculenta Crantz) roots during postharvest physiological deterioration. Food Chem. 161, 67-78. Doi: https://doi.org/10.1016/j.foodchem.2014.03.110

- Uchechukwu-Agua, A.D., O.J. Caleb, and U.L. Opara. 2015. Postharvest handling and storage of fresh cassava root and products: a review. Food Bioprocess Technol. 8, 729-748. Doi: https://doi.org/10.1007/s11947-015-1478-z

- Vanderschuren, H., E. Nyaboga, J. Poon, K. Baerenfaller, J. Grossmann, M. Hirsch-Hoffmann, N. Kirchgessner, P. Nanni, and W. Gruissem. 2014. Large-Scale proteomics of the cassava storage root and identification of a target gene to reduce postharvest deterioration. Plant Cell 26(5), 1913-1924. Doi: https://doi.org/10.1105/tpc.114.123927

- Vasile, C. and M. Baican. 2021. Progresses in food packaging, food quality, and safety-controlled-release antioxidant and/or antimicrobial packaging. Molecules 26(5), 1263. Doi: https://doi.org/10.3390/molecules26051263

- Vieira, E.A., J.F. Fialho, L. Julio, L.J.C.B. Carvalho, J.L.D. Corte, M.M. Rinaldi, C.M. Oliveira, F.D. Fernandes, and J.R.N. Anjos. 2018. Sweet cassava cultivars with yellow or cream root pulp developed by participatory breeding. Crop Breed. Appl. Biotechnol. 18(4), 450-454. Doi: https://doi.org/10.1590/1984-70332018v18n4c67

- Vieira, E.A., J.F. Fialho, M.S. Silva, S.V. Paula-Moraes, C.M. Oliveira, J.R.N. Anjos, M.M. Rinaldi, F.D. Fernandes, and R. Guimarães Júnior. 2011. BRS Japonesa: new sweet cassava cultivar for the Distrito Federal region. Crop Breed. Appl. Biotechnol. 11(2), 193-196. Doi: https://doi.org/10.1590/S1984-70332011000200014

- Vieites, R.L., E.R. Daiuto, L.R. Carvalho, M.R. Garcia, M.G. Lozano, and L.M. Watanabe. 2012. Mandioca minimamente processada submetida a radiação gama Fresh cut cassava subjected to gamma radiation. Semina: Ciênc. Agrár. 33(1), 271-282. Doi: https://doi.org/10.5433/1679-0359.2012v33n1p271

- Viera, E.A., J.F. Fialho, L. Julio, J.L.D. Corte, M.M. Rinaldi, C.M. Oliveira, F.D. Fernandez, and J.R.N. Anjos. 2020. BRS 396, BRS 397, BRS 398 e BRS 399 novas cultivares de mandioca de mesa com coloração da polpa das raízes amarela e creme. Comunicado Técnico No. 186. Embrapa Cerrados, Planaltina, Brazil.

- Zainuddin, I.M., A. Fathoni, E. Sudarmonowati, J.R. Beeching, W. Gruissem, and H. Vanderschuren. 2018. Cassava post-harvest physiological deterioration: from triggers to symptoms. Postharvest Biol. Technol. 142, 115-123. Doi: https://doi.org/10.1016/j.postharvbio.2017.09.004

- Zidenga, T., E. Leyva-Guerrero, H. Moon, D. Siritunga, and R. Sayre. 2012. Extending cassava root shelf life via reduction of reactive oxygen species production. Plant Physiol. 159(4), 1396-1407. Doi: https://doi.org/10.1104/pp.112.200345